About Us

We provide the best service and focus on precision and standards which gives our clients the best quality and great experience.

We measure our success by our ability to fulfil customers’ orders with the highest degree of efficiency and reliability.

Our employees are one of the best and highly skilled and have worked on various projects and workpieces.

We use different types of materials as per their function and application. Special graded materials can also be used as per clients’ requirements and we procure it from the best and trusted vendors.

A variety of cutting tools and inserts are used for cutting the workpiece as desired.

We conduct a deep study on drawings provided by our clients and use different ways to create a workpiece in less time and greater standards.

We provide high-quality machining that delivers superior quality products in the most efficient and economical manner.

Afterall we not only run our business but we also help to run your business and feel proud in working with our clients.

We manufacture various Tyre moulds Ancillaries items like curing rings, clamp rings, BPR, Ply Cuff Bead Flanges, Drum spacers & standard rims and all the engineering items.

We have worked with companies like CEAT TYRES Ltd.

We are dealing with India's leading tyre and rubber companies and try to generate new ways for greater efficiency.

Our heavy-duty machines are capable of holding jobs up to 1500mm swing diameter.

Our Facilities

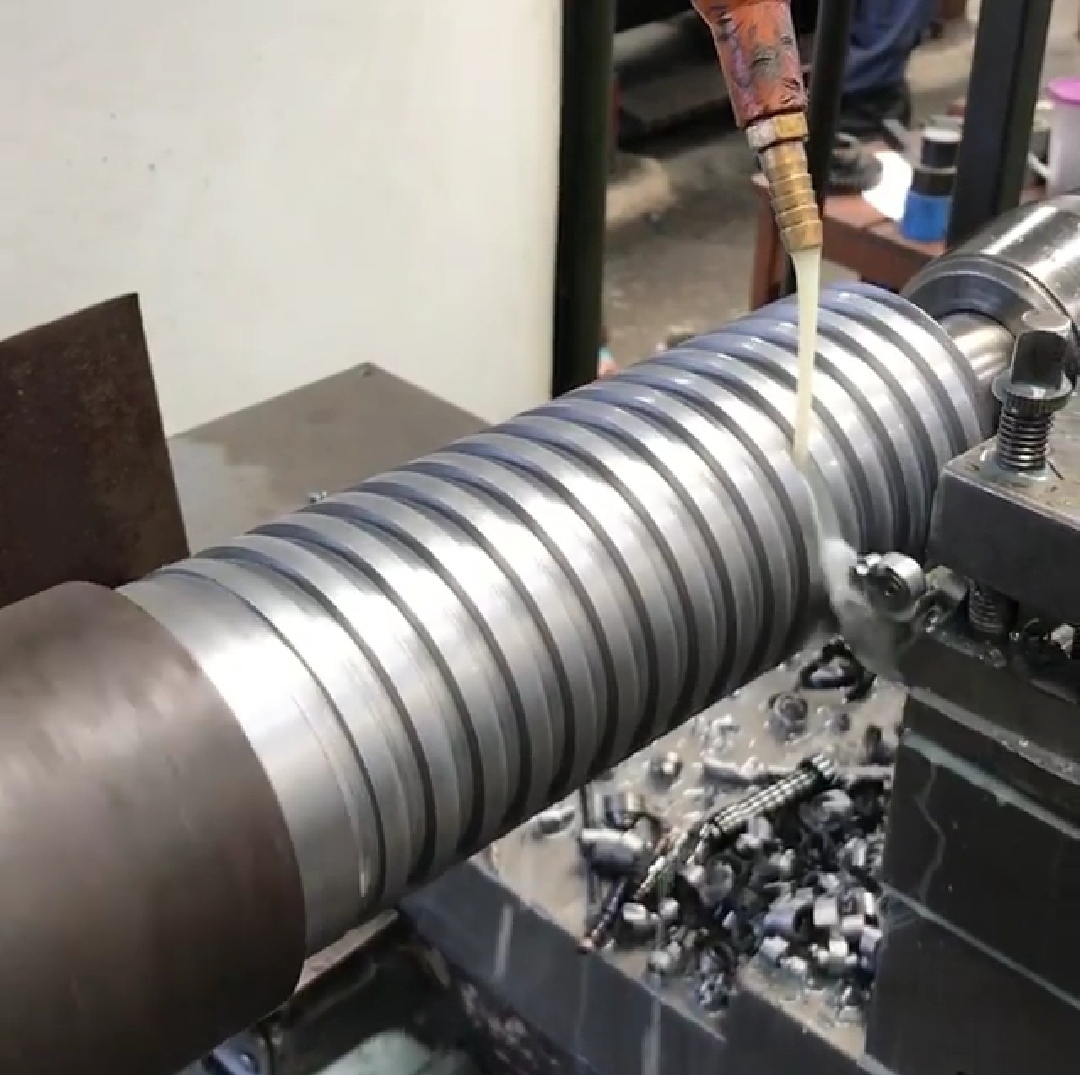

Machining

Machining is a manufacturing term encompassing a broad range of technologies and techniques. It can be roughly defined as the process of removing material from a workpiece using power-driven machine tools to shape it into an intended design.

When we say machining it include all process like turning, facing, knurling, grooving, thread cutting and milling.

Grinding

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

It can produce very fine finish and very accurate dimensions. We use a variety of power tools as well as grindstones for metal chip removal.

Drilling

Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute.

Our tools include hand drills as well as radial drilling equipments and we can drill in any material provided by our vendors.

Welding

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool.

We usually carry welding on various types of metal and use different types of welding like arc welding and gas welding. We also use lower temperature metal joining techniques like brazing and soldering if required.

Polishing

Polishing and buffing are finishing processes for smoothing a workpiece's surface using various power tools and chemicals.

Technically polishing refers to processes that uses chemical and skills that gives our workpiece smooth and shiny finish and leaves the surface with specular reflection.

Stamping

Stamping (also known as pressing) is the process of placing sheet metal and pressed with desired punches as per vendor requirements.

We do various types of letter and number stamping and these services are available in both forward and reverse type.

WE ALSO MANUFACTURE ENGINEERING PARTS LIKE

Gear

∘ A gear is a rotating machine part having cut teeth which mesh with another toothed part to transmit torque.

We produce various types of gears for greater performance as per clients needs and for greater efficiency.

We manufacture various types of gear like spur, gear, helical gear and rack & pinion and many more.

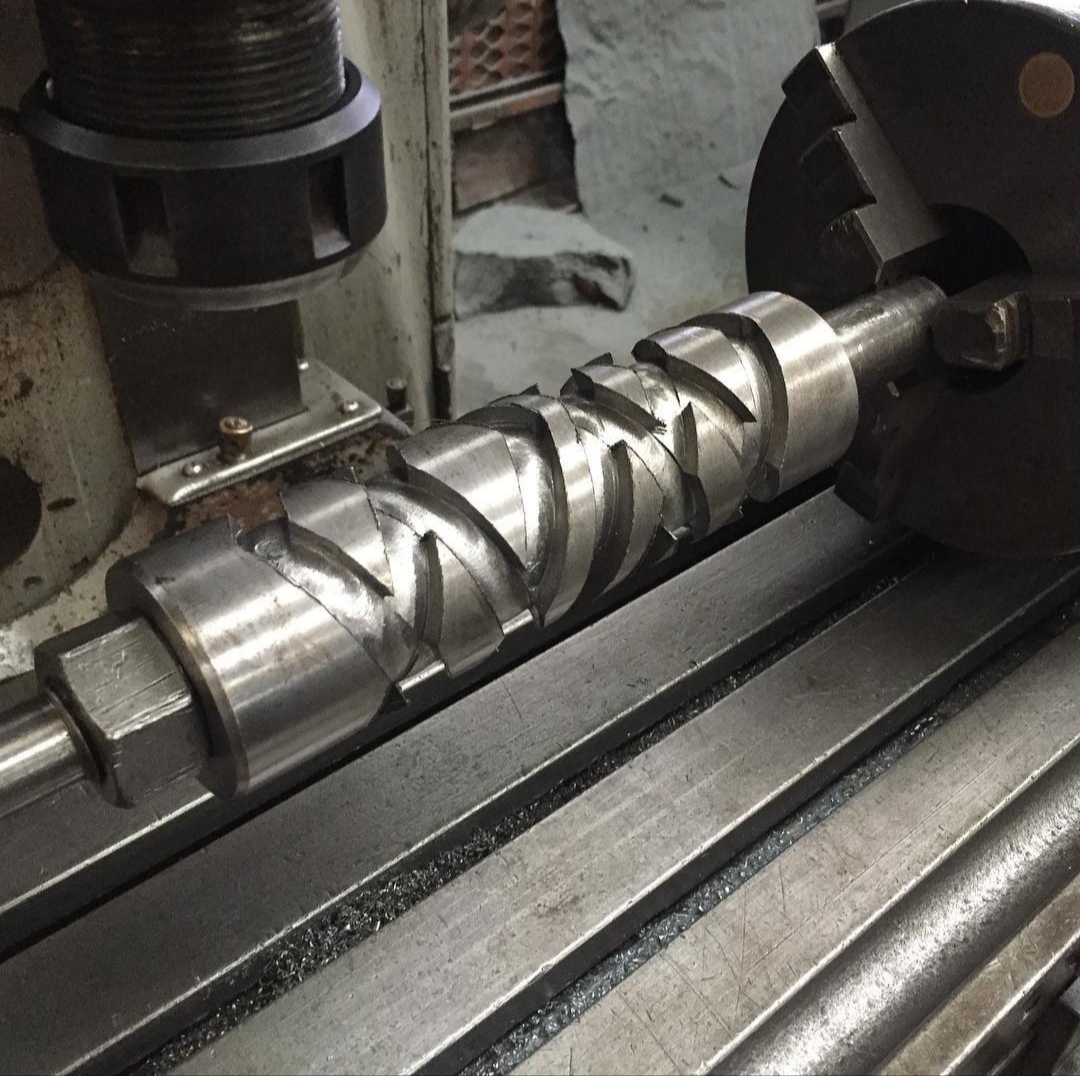

Shaft

∘ A shaft is a rotating machine element, usually circular in cross section, which is used to transmit power from one part to another, or from a machine which produces power to a machine which absorbs power.

We produce different types of shafts in all types of material as per clients requirement.

We produce all types of screw shafts.

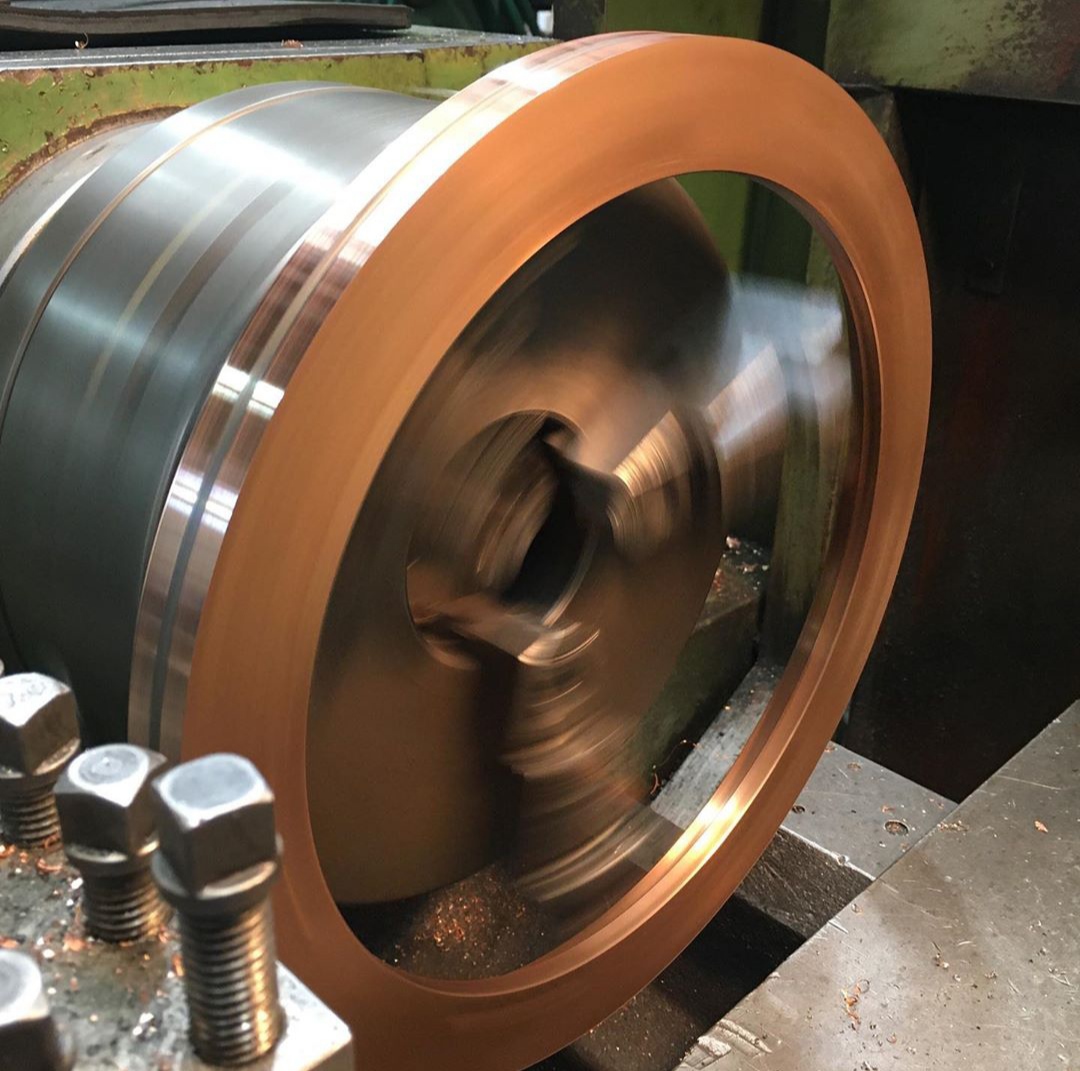

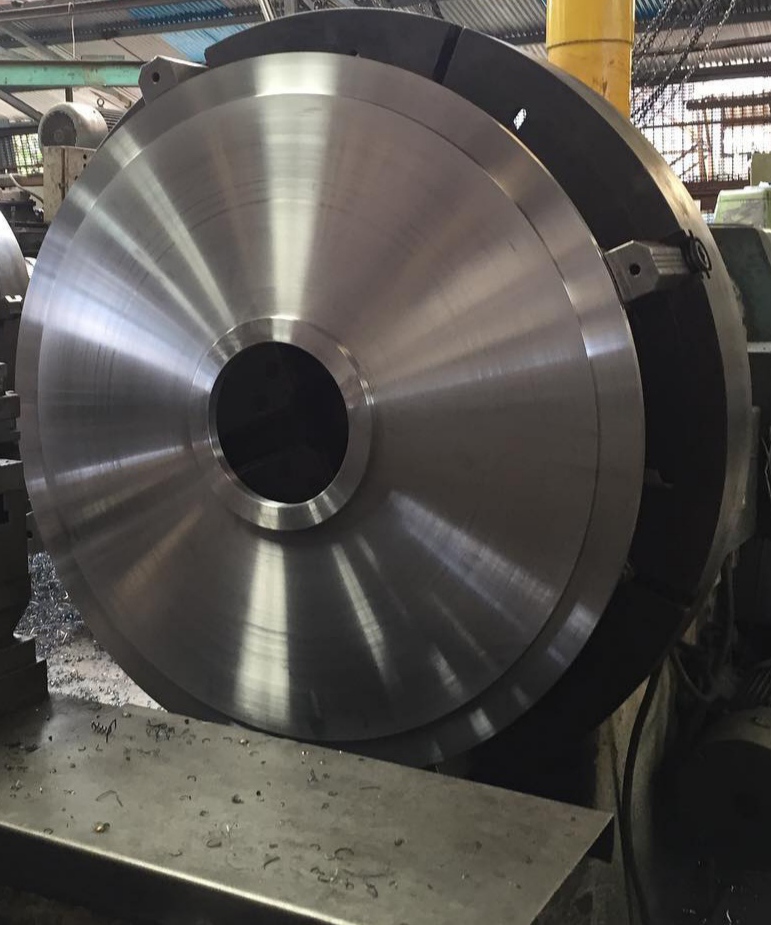

Rings

∘ We can manufacture all types of rings as per designs provided by our clients.

Our heavy duty machines are capable of holding jobs upto 1500mm swing diameter.

We not only make the above mentioned rings for tyre industry but also cater to other clients and fulfill their requirements.

Contact

If you have any further queries, please do not hesitate to contact us.

Address

906, ST. THOMAS CHURCH RD, SANDOR

BANGLI NAKA, VASAI WEST 401201

Call Us

Working Hours

Mon - Sat: 9AM to 5PM